(1) Grade 80 welded lifting chain WLL and index

Table 1: WLL with chain sling leg(s) angle of 0°~90°

|

Link diameter (mm) |

Max. WLL |

||

|

Single leg t |

2-leg t |

3 or 4 leg t |

|

|

7.1 |

1.6 |

2.2 |

3.3 |

|

8.0 |

2.0 |

2.8 |

4.2 |

|

9.0 |

2.5 |

3.5 |

5.2 |

|

10.0 |

3.2 |

4.4 |

6.7 |

|

11.2 |

4.0 |

5.6 |

8.4 |

|

12.5 |

5.0 |

7.0 |

10.5 |

|

14.0 |

6.3 |

8.8 |

13.2 |

|

16.0 |

8.0 |

11.2 |

16.8 |

|

18.0 |

10.0 |

14.0 |

21.0 |

Table 2: WLL index

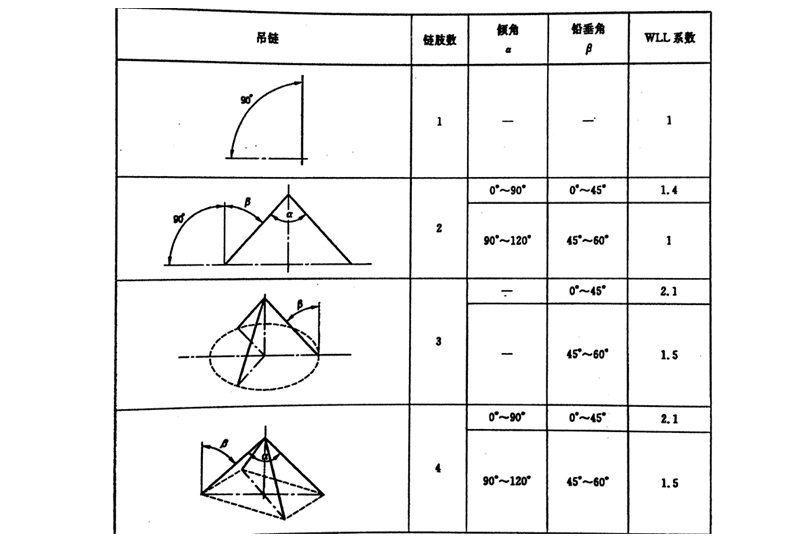

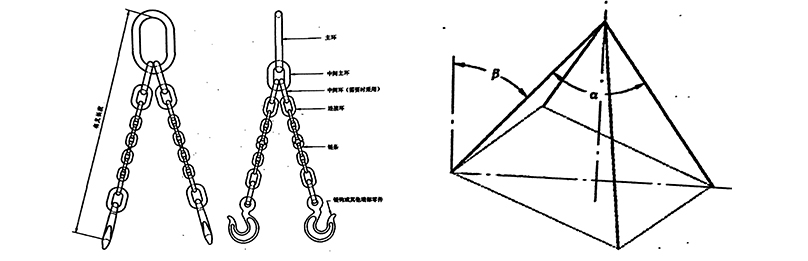

(2) chain sling types and legs angle

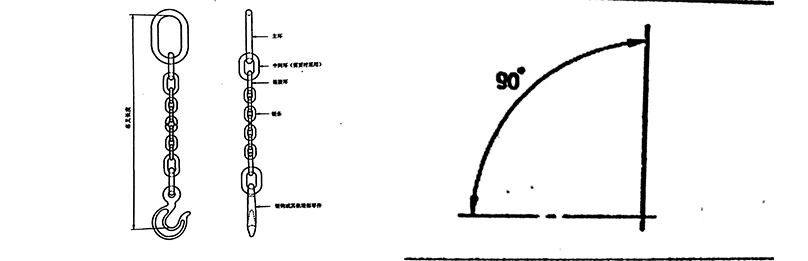

a. single leg chain sling

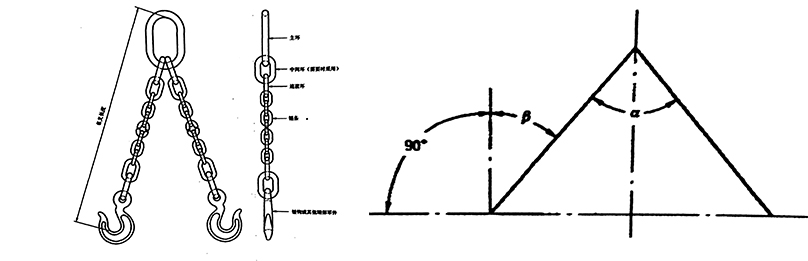

b. 2-leg chain sling

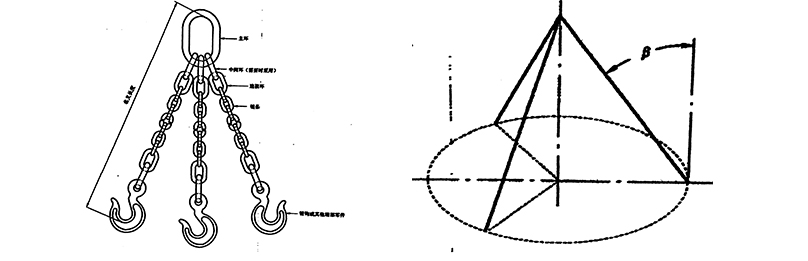

c. 3-leg chain sling

d. 4-leg chain sling

(3) lifting round link chain use

a. the load weight shall be equal or less than lifting chain sling max. WLL.

b. when using 2-leg or multi leg chain sling, the bigger sling legs angle, the less load it can lift; legs angle shall be less than 120°in any case (i.e., chain leg angle with vertical lead angle shall be less than 60°).

c. when lifting in choker hitch, the load shall be less than 80% WLL.

d. The lifting chain shall be straight without torsion, knotting or bending. Try to avoid heavy objects rolling on the chain.

(1) daily inspection

a. Inspector, frequency and records

The operator or designated personnel shall conduct routine appearance inspection on the lifting chain every working day, and there shall be a record of "daily point inspection form of sling" (see Annex) on site, indicating that the sling can be used normally.

b. Visual inspection

Visually check the appearance for signs of serious wear, deformation or external damage. If defects are found in the inspection, confirm whether it can be used again according to the regular inspection method.

(2) Periodic inspection

a. Inspector, frequency and records

The designated personnel shall conduct a comprehensive inspection on the chain according to the defect signs proposed by the regular inspection, and make records to evaluate whether the chain can continue to be used.

b. Check points

i)Whether the external marks such as lifting chain mark and ultimate working load are clear;

ii) The upper and lower end connectors (master link, intermediate link, connectors and hooks) of the lifting chain are deformed, cut and cracked, which exceed the standard requirements and cannot be used;

iii) Deformation of chain link: the chain link is twisted, bent and elongated, and cannot be used when it exceeds the standard requirements;

iv) Link wear: the notch, notch, gouge and wear of the link on the outside of the straight section cannot be used when it exceeds the standard requirements;

v) Hook deformation: the "opening" deformation and distortion of the openness of the hook exceed the standard requirements and cannot be used;

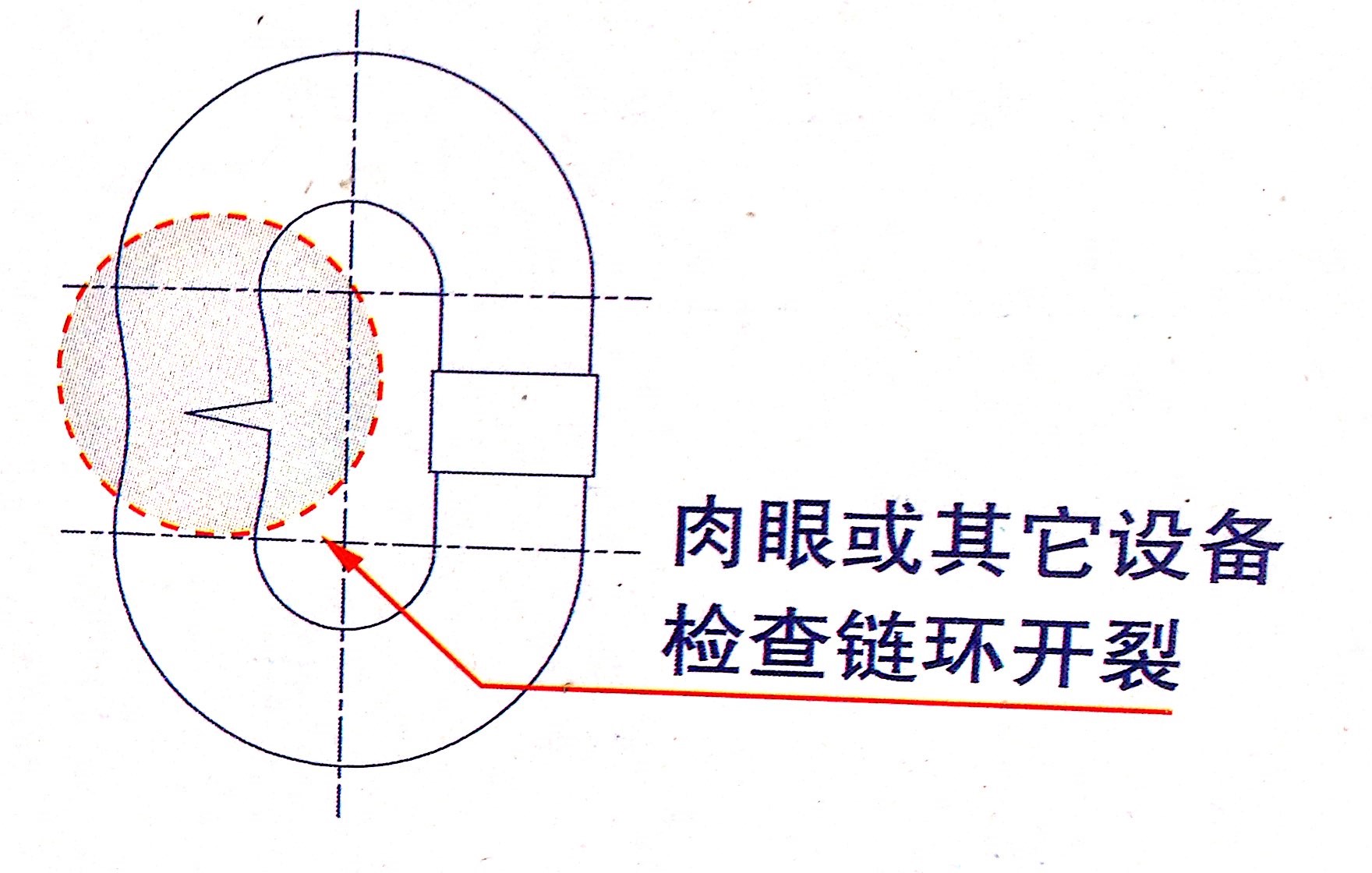

vi) Cracks: cracks proved by visual observation or NDT cannot be used.

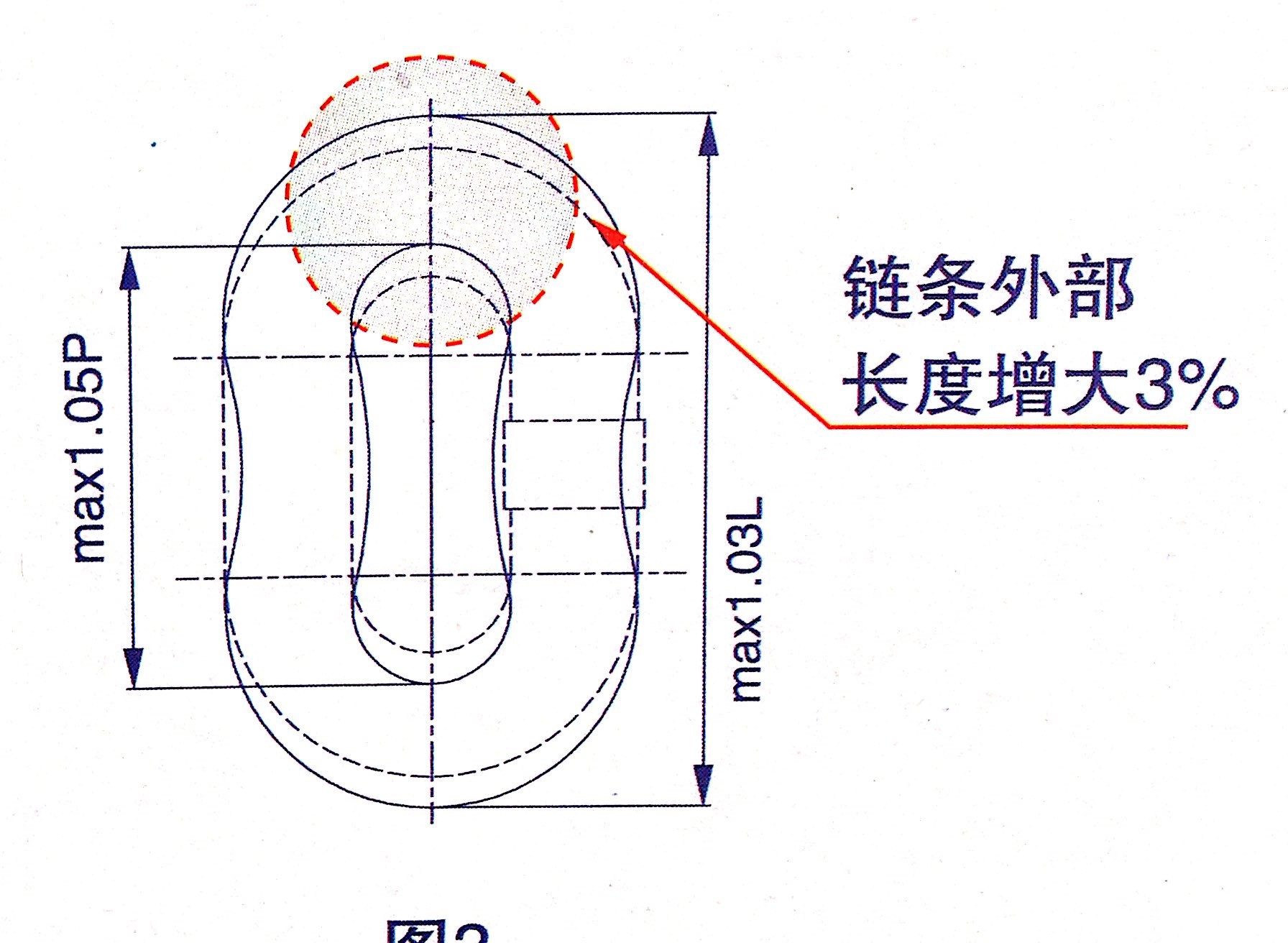

a. deformation:

outer length elongation>3%

inner length elongation>5%

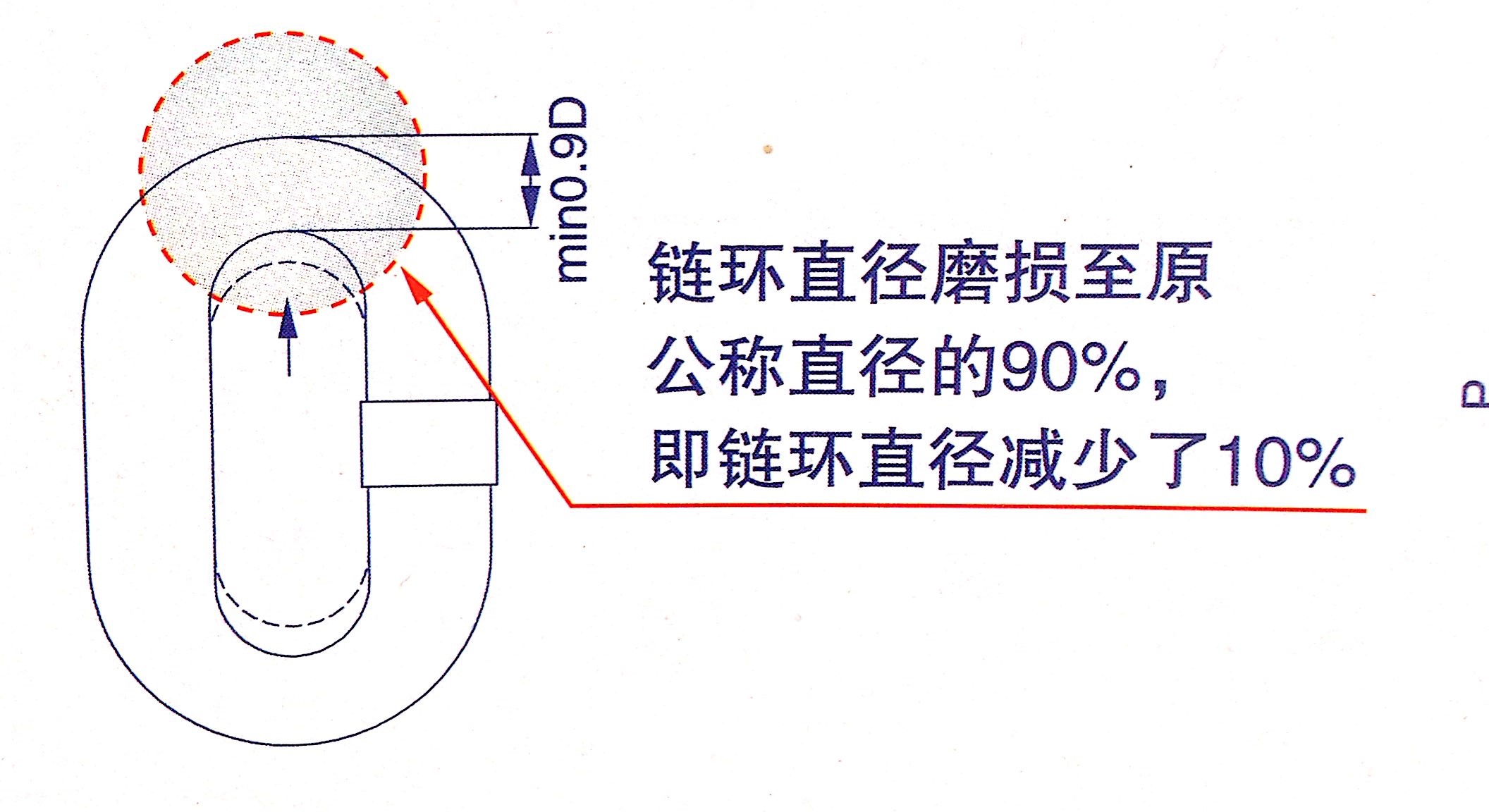

b. wearing:

link cross section diameter after wearing shall not be less by 10% (i.e., diameter < 90% the nominal)

c. cracks:

No crack is allowed on the surface of the chain link through visual inspection or equipment inspection.

d. bending or distortion:

No obvious bending or distortion, serious corrosion or attachment that cannot be removed is allowed for the chain link.

(2) hook

a. Hook opening: the increase of hook opening size shall not exceed 10% of the nominal value.

b. Wear of stressed (dangerous) section: the thickness of the section at the wear point shall not be reduced by more than 5%

c. Twist deformation: the twist deformation of hook body shall not exceed 5%.

d. Cracks: cracks are not allowed on the whole hook surface by visual inspection or equipment inspection.

e. Nicks and gouges: they can be repaired by grinding or filing. The repaired surface and adjacent surfaces shall transition smoothly without abrupt changes in the section. The thickness of the polished section shall not be reduced by more than 5%.

(3) master link

a. Distortion: the distortion of the whole master link shall not exceed 5%.

b. Wear: the wear of the master link surface shall not exceed 10% of the original diameter

c. Cracks: cracks are not allowed on the whole master link surface by visual inspection or equipment inspection.

(4) shackles and other accessories

a. Opening: the opening size of shackle exceeds 10% of the original value.

b. Wear: the diameter of the pin or pin shaft is worn more than 10% of the original diameter; the wear of the stressed (dangerous) section is more than 5%

c. Crack: no crack is allowed on the whole accessory surface through visual inspection or equipment inspection.

(1) Normal chain links

(2) Deformed hook (scrapped)

(3) Deformation, wear and cratering of chain links (scrapping)

(4) Local wear on the surface of the chain link (can be repaired)

(5) The chain link is slightly worn and deformed (it can continue to be used)

Post time: Dec-17-2021