Mining Chains – 10*40mm DIN22252 Round Link Chain

Category

Application

Related Products

Chain Parameter

SCIC Round Link Chain is made according to China GB/T-12718 standard and factory Technical Requirements, as well as to DIN 22252 or GOST 25996 standards and clients specs

SCIC Round Link Chain is used for Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), road header machines, coal plows and other equipment that requires this type of chain.

Anti-corrosive coatings (e.g., hot dipped galvanization) result in decreased chain mechanical properties, therefore the application of any anti-corrosive coatings shall subject to order agreement between buyer and SCIC.

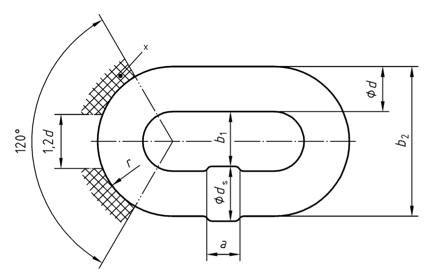

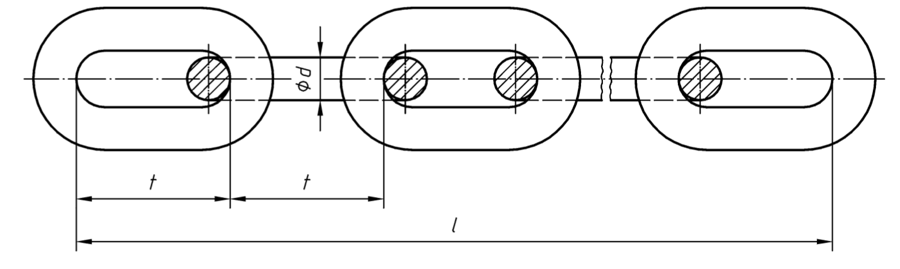

Figure 1: round link chain

Table 1: round link chain dimensions

|

link size (opp. Weld) |

pitch |

link width |

link weld size |

unit weight |

||||

|

nominal |

tolerance |

nominal |

tolerance |

inner |

outer |

diameter |

length |

|

|

10 |

± 0.4 |

40 |

±0.5 |

12 |

34 |

10.8 |

7.1 |

1.9 |

|

14 |

± 0.4 |

50 |

±0.5 |

17 |

48 |

15 |

10 |

4.0 |

|

18 |

± 0.5 |

64 |

±0.6 |

21 |

60 |

19.5 |

13 |

6.6 |

|

19 |

± 0.6 |

64.5 |

±0.6 |

22 |

63 |

20 |

13 |

7.4 |

|

22 |

± 0.7 |

86 |

±0.9 |

26 |

74 |

23.5 |

15.5 |

9.5 |

|

24 |

± 0.8 |

86 |

±0.9 |

28 |

79 |

26 |

17 |

11.6 |

|

26 |

± 0.8 |

92 |

±0.9 |

30 |

86 |

28 |

18 |

13.7 |

|

30 |

± 0.9 |

108 |

±1.1 |

34 |

98 |

32.5 |

21 |

18.0 |

|

34 |

± 1.0 |

126 |

±1.3 |

38 |

109 |

36.5 |

23.8 |

22.7 |

|

38 |

± 1.1 |

126 |

±1.3 |

42 |

121 |

41 |

27 |

30.1 |

|

38 |

± 1.1 |

137 |

±1.4 |

42 |

121 |

41 |

27 |

29.0 |

|

42 |

± 1.3 |

137 |

±1.4 |

48 |

137 |

45 |

30 |

36.9 |

|

42 |

± 1.3 |

146 |

±1.5 |

48 |

137 |

45 |

30 |

36.0 |

|

42 |

± 1.3 |

152 |

±1.5 |

46 |

133 |

45 |

30 |

35.3 |

|

notes: Larger size chain available upon inquiry. |

||||||||

Table 2: round link chain mechanical properties

|

chain size |

chain grade |

test force |

elongation under test force |

breaking force |

elongation at fracture |

minimum deflection |

|

10 x 40 |

S |

85 |

1.4 |

110 |

14 |

10 |

|

SC |

100 |

1.6 |

130 |

|||

|

SCC |

130 |

1.9 |

160 |

|||

|

14 x 50 |

S |

150 |

1.4 |

190 |

14 |

14 |

|

SC |

200 |

1.6 |

250 |

|||

|

SCC |

250 |

1.9 |

310 |

|||

|

18 x 64 |

S |

260 |

1.4 |

320 |

14 |

18 |

|

SC |

330 |

1.6 |

410 |

|||

|

SCC |

410 |

1.9 |

510 |

|||

|

19 x 64.5 |

S |

290 |

1.4 |

360 |

14 |

19 |

|

SC |

360 |

1.6 |

450 |

|||

|

SCC |

450 |

1.9 |

565 |

|||

|

22 x 86 |

S |

380 |

1.4 |

480 |

14 |

22 |

|

SC |

490 |

1.6 |

610 |

|||

|

SCC |

610 |

1.9 |

760 |

|||

|

24 x 86 |

S |

460 |

1.4 |

570 |

14 |

24 |

|

SC |

580 |

1.6 |

720 |

|||

|

SCC |

720 |

1.9 |

900 |

|||

|

26 x 92 |

S |

540 |

1.4 |

670 |

14 |

26 |

|

SC |

680 |

1.6 |

850 |

|||

|

SCC |

850 |

1.9 |

1060 |

|||

|

30 x 108 |

S |

710 |

1.4 |

890 |

14 |

30 |

|

SC |

900 |

1.6 |

1130 |

|||

|

SCC |

1130 |

1.9 |

1410 |

|||

|

34 x 126 |

S |

900 |

1.4 |

1140 |

14 |

34 |

|

SC |

1160 |

1.6 |

1450 |

|||

|

SCC |

1450 |

1.9 |

1810 |

|||

|

38 x 126 |

S |

1130 |

1.4 |

1420 |

14 |

38 |

|

SC |

1450 |

1.6 |

1810 |

|||

|

SCC |

1810 |

1.9 |

2270 |

|||

|

42 x 137 |

S |

1390 |

1.4 |

1740 |

14 |

42 |

|

SC |

1770 |

1.6 |

2220 |

|||

|

SCC |

2220 |

1.9 |

2770 |