Wholesale Dealers of Stainless Steel Snake Chain - Conveyor and elevator chains – Chigong

Wholesale Dealers of Stainless Steel Snake Chain - Conveyor and elevator chains – Chigong Detail:

Category

Lifting chain, short link chain, long link chain, round link chain, chain lifting, lifting chains, Grade 50 chain, Grade 70 chain, DIN 764-1, DIN 764-2, DIN 766, Round steel link chains for chain conveyor Conveyor chain, bucket elevator chain, alloy steel chain

Application

Bucket elevator, conveyor, scraper Chains for bucket elevator, conveyor and scraper SCIC produce round steel link chains per DIN 764 (G30 & G50, 2010 version) and DIN 766 (2015 version) standards, for applications in bucket elevator, conveyor and scraper. Chains specified here shall not be used as lifting accessories, slings or any other overhead hoisting.

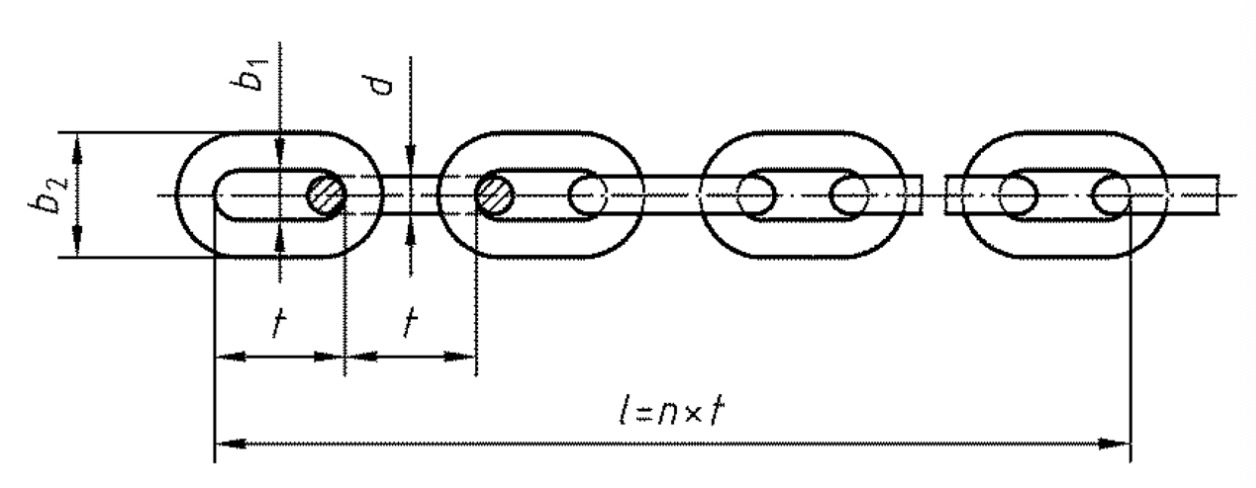

Figure 1: DIN 764 and DIN 766 round steel link chain dimensions

Table 1: DIN 764 round steel link chain (G30 & G50) dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

classA |

class B |

|||||||||

|

10 x 35 |

10 |

± 0.4 |

35 |

+0.6/-0.2 |

14.0 |

36 |

385 |

+2/-1 |

+3/-1 |

2.1 |

|

13 x 45 |

13 |

± 0.5 |

45 |

+0.8/-0.3 |

18.0 |

47 |

495 |

+3/-1 |

+4/-1 |

3.5 |

|

16 x 56 |

16 |

± 0.6 |

56 |

+1.0/-0.3 |

22.0 |

58 |

616 |

+3/-1 |

+5/-2 |

5.3 |

|

18 x 63 |

18 |

± 0.9 |

63 |

+1.1/-0.4 |

24.0 |

65 |

693 |

+4/-1 |

+6/-2 |

6.7 |

|

20 x 70 |

20 |

± 1.0 |

70 |

+1.3/-0.4 |

27.0 |

72 |

770 |

+4/-1 |

+6/-2 |

8.3 |

|

23 x 80 |

23 |

± 1.2 |

80 |

+1.4/-0.5 |

31.0 |

83 |

880 |

+5/-2 |

+7/-2 |

11.0 |

|

26 x 91 |

26 |

± 1.3 |

91 |

+1.6/-0.5 |

35.0 |

94 |

1001 |

+5/-2 |

+8/-3 |

14.0 |

|

30 x 105 |

30 |

± 1.5 |

105 |

+1.9/-0.6 |

39.0 |

108 |

1155 |

+6/-2 |

+9/-3 |

18.5 |

|

33 x 115 |

33 |

± 1.7 |

115 |

+2.1/-0.7 |

43.0 |

119 |

1265 |

+7/-2 |

+10/-3 |

22.5 |

|

36 x 126 |

36 |

± 1.8 |

126 |

+2.3/-0.8 |

47.0 |

130 |

1386 |

+7/-2 |

+11/-4 |

27.0 |

|

39 x 136 |

39 |

± 2.0 |

136 |

+2.4/-0.8 |

51.0 |

140 |

1496 |

+8/-3 |

+12/-4 |

31.5 |

|

42 x 147 |

42 |

± 2.1 |

147 |

+2.6/-0.9 |

55.0 |

151 |

1617 |

+9/-3 |

+13/-4 |

36.5 |

Table 2: DIN 766 round steel link chain dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

class A |

class B |

|||||||||

|

10 x 28 |

10 |

± 0.4 |

28 |

+0.5/-0.3 |

14.0 |

36 |

308 |

+2 /-1 |

+2 /-1 |

2.3 |

|

13 x 36 |

13 |

± 0.5 |

36 |

+0.6/-0.3 |

18.0 |

47 |

396 |

+2 /-1 |

+3 /-2 |

3.9 |

|

16 x 45 |

16 |

± 0.6 |

45 |

+0.8/-0.4 |

22.5 |

58 |

496 |

+3 /-1 |

+4 /-2 |

5.9 |

|

18 x 50 |

18 |

± 0.9 |

50 |

+0.9/-0.5 |

25.0 |

65 |

550 |

+3 /-1 |

+4 /-2 |

7.5 |

|

20 x 56 |

20 |

± 1.0 |

56 |

+1.0/-0.5 |

28.0 |

72 |

616 |

+3 /-2 |

+5 /-2 |

9.2 |

|

23 x 64 |

23 |

± 1.2 |

64 |

+1.2/-0.6 |

32.0 |

83 |

704 |

+4 /-2 |

+6 /-3 |

12.0 |

|

26 x 73 |

26 |

± 1.3 |

73 |

+1.3/-0.7 |

34.0 |

94 |

803 |

+4 /-2 |

+6 /-3 |

15.5 |

|

30 x 84 |

30 |

± 1.5 |

84 |

+1.5/-0.8 |

39.0 |

108 |

924 |

+5 /-2 |

+7 /-4 |

20.5 |

|

33 x 92 |

33 |

± 1.7 |

92 |

+1.7/-0.8 |

43.0 |

119 |

1012 |

+5 /-3 |

+8 /-4 |

25.0 |

|

36 x 101 |

36 |

± 1.8 |

101 |

+1.8/-0.9 |

47.0 |

130 |

1111 |

+6 /-3 |

+9 /-4 |

29.5 |

|

39 x 109 |

39 |

± 2.0 |

109 |

+2.0/-1.0 |

50.5 |

140 |

1199 |

+6 /-3 |

+10 /-5 |

35.0 |

|

42 x 118 |

42 |

± 2.1 |

118 |

+2.1/-1.1 |

54.5 |

151 |

1298 |

+7 /-4 |

+10 /-5 |

40.5 |

Table 3: DIN 764 round steel link chain (G30 & G50) working force and mechanical properties

|

nominal size |

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|||||

|

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

|

|

10 x 35 |

12.5 |

20 |

36 |

56 |

50 |

80 |

10 |

10 |

20 |

15 |

|

13 x 45 |

20 |

32 |

56 |

90 |

80 |

125 |

13 |

13 |

||

|

16 x 56 |

32 |

50 |

90 |

140 |

125 |

200 |

16 |

16 |

||

|

18 x 63 |

40 |

63 |

110 |

180 |

160 |

250 |

18 |

18 |

||

|

20 x 70 |

50 |

80 |

140 |

220 |

200 |

320 |

20 |

20 |

||

|

23 x 80 |

63 |

100 |

180 |

280 |

250 |

400 |

23 |

23 |

||

|

26 x 91 |

80 |

125 |

220 |

360 |

320 |

500 |

26 |

26 |

||

|

30 x 105 |

110 |

180 |

320 |

500 |

450 |

710 |

30 |

30 |

||

|

33 x 115 |

125 |

200 |

360 |

560 |

500 |

800 |

33 |

33 |

||

|

36 x 126 |

160 |

250 |

450 |

710 |

630 |

1000 |

36 |

36 |

||

|

39 x 136 |

180 |

280 |

500 |

800 |

710 |

1100 |

39 |

39 |

||

|

42 x 147 |

220 |

360 |

630 |

1000 |

900 |

1400 |

42 |

42 |

||

Table 4: DIN 766 round steel link chain working force and mechanical properties

|

nominal size

|

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|

|

vertical |

horizontal |

|||||

|

10 x 28 |

10 |

12.5 |

36 |

50 |

8 |

20 |

|

13 x 36 |

16 |

20 |

56 |

80 |

10 |

|

|

16 x 45 |

25 |

32 |

90 |

125 |

13 |

|

|

18 x 50 |

32 |

40 |

110 |

160 |

14 |

|

|

20 x 56 |

40 |

50 |

140 |

200 |

16 |

|

|

23 x 64 |

50 |

63 |

180 |

250 |

18 |

|

|

26 x 73 |

63 |

80 |

220 |

320 |

21 |

|

|

30 x 84 |

90 |

110 |

320 |

450 |

24 |

|

|

33 x 92 |

110 |

130 |

380 |

530 |

26 |

|

|

36 x 101 |

125 |

160 |

450 |

630 |

29 |

|

|

39 x 109 |

150 |

190 |

530 |

750 |

31 |

|

|

42 x 118 |

180 |

220 |

630 |

900 |

34 |

|

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Wholesale Dealers of Stainless Steel Snake Chain - Conveyor and elevator chains – Chigong, The product will supply to all over the world, such as: Tunisia, Vietnam, US, We now have to continue to uphold the "quality, detailed, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!