Chain is often used to tie down loads, for lifting applications and to tow loads – however, the rigging industry’s safety standards have developed in recent years, and chain used for lifting must meet certain specifications.

Chain slings are among some of the most popular options to lift a load, they’re often used to lift spreader beams, for example. Chain slings are durable, ductile, can resist high temperatures, rips & tears and in certain applications, are adjustable. but how do you determine the best chain sling for your project needs?

Two types of chain slings are used to for rigging and lifting applications – mechanical assembly and welded assembly. Chain slings are made with a minimum safety factor of 4:1.

The most common chain slings used in rigging and lifting are mechanically assembled since they’re quick to produce and it can be done with basic tools. Chain slings are made by a variety of manufacturers and in many different configurations.

1. Mechanically Assembled Chain Sling Hardware

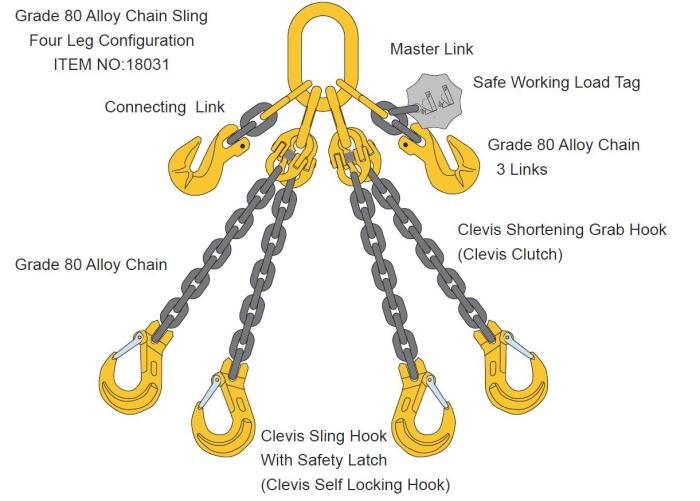

Construct a basic mechanically assembled chain sling with these hardwares:

● Master Link

● Mechanical Jointing Device (i.e., connecting link)

● Shortening Clutch (if required)

● Round Link Chain

● Sling Hook (other fitting as required)

● Tag

2. Welded Assembly

Welded chain slings are less commonly used. They take more time to manufacture, since once they’re made they undergo a heat treatment so they’re safe to use in a lifting application. This takes days, versus the minutes it takes to together a mechanically assembled chain sling.

Construct a welded assembly chain sling with this hardware:

● Master Link

● Welded Intermediate Link

● Welded Connecting Link

● Chain

● Hook (other fittings if required)

● Tag

3. How To Assemble A Chain Sling With Correct Chain Grades?

The marking grade for chains is recognized by numbers which are found on the chain link. Chain grades for chain sling assembly start at Grade 80 – Grade 80, 100 and 120 are used for lifting applications. Do not use grade 30, 40 or 70 chains for overhead lifting.

These grades are used for lifting as they’re ductile and can cope with “shock-loading” that can happen while rigging.

4. How To Find The Right Chain Sling Assembly For You?

Follow these steps to assemble the best chain sling for your lifting needs.

1. Determine the weight of the load to lift, it’s working load limit and any angles that will affect the lift.

2. Head to the dimension/specification chart provided by the chain sling’s manufacturer. Find the chain sling configuration that will suit your load and lift.

3. Head to the assembly chart found in the catalogue or website of your respective distributer. Find the Working Load Limit (WLL) to lift at the top of the chart. Find the column that represents size/length, which will be donated in centimetres, inches or millimetres. Be sure to size up. Example: if your load’s WLL is 3,000lbs the chart may give you two options – a WLL of 2,650 and 4,500. Choose the chain length that corresponds with the WLL of 4,500lbs – it’s better to have too much capacity than not enough.

4. Use the same instructions from Step 3 to choose hardware/fittings from the respective specification chart(s). Example: You’ve chose the DOG sling configuration – this means you must find an oblong shaped master link and a grab hook that corresponds to the WLL.

For example: Bob is planning to lift a load with a WLL of 3,000lbs and wants to assemble a chain sling.

Step 1) Bob finds the WLL column of his retailer.

Step 2) Find the WLL – since 3,000lbs isn’t on the chart, we choose the next one up which has a WLL of 4,500lbs.

Step 3) Bob needs chain with 1.79in. length.

Post time: Apr-04-2022