Bar cutting → cold bending → jointing → welding → primary calibration → heat treatment → secondary calibration (proof) → inspection. Welding and heat treatment are the key processes in the production of mining round link steel chain, which directly affect the product quality. Scientific welding parameters can improve the yield and reduce the production cost; Appropriate heat treatment process can give full play to material properties and improve product quality.

In order to ensure the welding quality of mining round link steel chain, manual arc welding and resistance butt welding have been eliminated. Flash butt welding is widely used because of its high degree of automation, low labor intensity, stable product quality and other outstanding advantages.

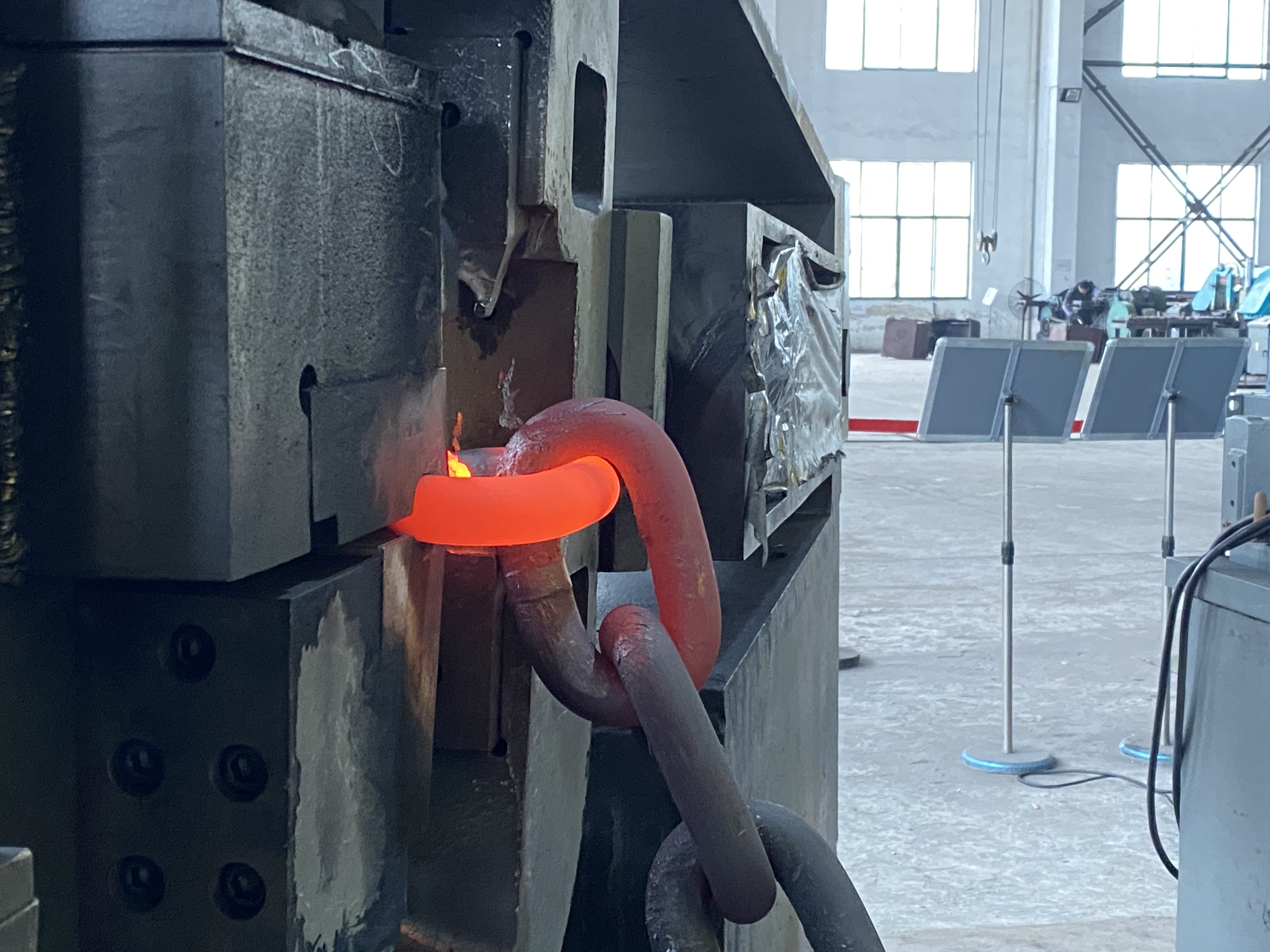

At present, the medium frequency induction heating continuous quenching and tempering method is generally used in the heat treatment of the mining round link steel chain. The essence of medium frequency induction heating is that the molecular structure of an object is stirred under electromagnetic field, and the molecule gets energy and collides to generate heat. When the medium frequency induction heat treatment is conducted, the inductor is connected with medium frequency alternating current of a certain frequency, and the workpiece moves at a uniform speed in the sensor, so that an induction current with the same frequency and opposite direction will be generated in the workpiece, which will change the electric energy into heat energy, and the workpiece will be heated to the temperature required by quenching and tempering in a short time.

The medium frequency induction heating has the advantages of fast heating speed, less oxidation, fine quenching structure and austenite grain size after quenching, which improves the strength and toughness of the chain link. At the same time, it also has the advantages of cleanness, easy adjustment and high production efficiency. In the tempering stage, the high tempering temperature in the chain link welding zone can eliminate the quenching internal stress in a short time, which has a very significant effect on improving the plasticity and toughness of the chain link welding zone and delaying the initiation and development of cracks. The tempering temperature at the top of the shoulder is lower, and the hardness is higher after tempering, which is conducive to the wear of the chain link in the process of working and against the hinge between the chain links and the sprocket meshing.

Post time: May-10-2021