High reputation Outboard Flight Bars - Conveyor and Elevator Chains – 18*50mm DIN 766 Round Steel Link Chain – Chigong

High reputation Outboard Flight Bars - Conveyor and Elevator Chains – 18*50mm DIN 766 Round Steel Link Chain – Chigong Detail:

Category

Application

Bucket elevator, conveyor, scraper Chains for bucket elevator, conveyor and scraper SCIC produce round steel link chains per DIN 764 (G30 & G50, 2010 version) and DIN 766 (2015 version) standards, for applications in bucket elevator, conveyor and scraper. Chains specified here shall not be used as lifting accessories, slings or any other overhead hoisting.

Chain Parameter

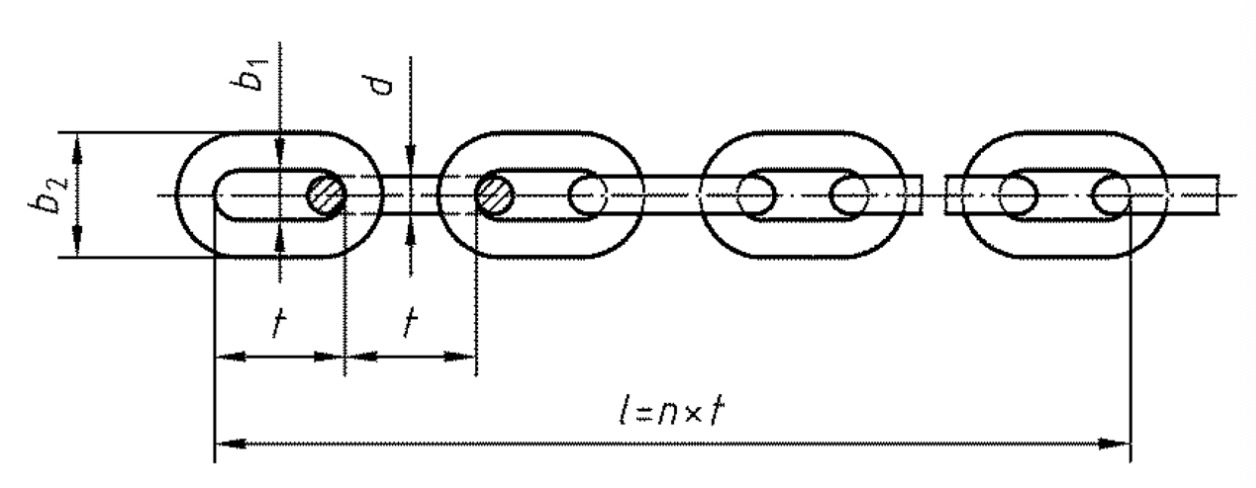

Figure 1: DIN 764 and DIN 766 round steel link chain dimensions

Table 1: DIN 764 round steel link chain (G30 & G50) dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

classA |

class B |

|||||||||

|

10 x 35 |

10 |

± 0.4 |

35 |

+0.6/-0.2 |

14.0 |

36 |

385 |

+2/-1 |

+3/-1 |

2.1 |

|

13 x 45 |

13 |

± 0.5 |

45 |

+0.8/-0.3 |

18.0 |

47 |

495 |

+3/-1 |

+4/-1 |

3.5 |

|

16 x 56 |

16 |

± 0.6 |

56 |

+1.0/-0.3 |

22.0 |

58 |

616 |

+3/-1 |

+5/-2 |

5.3 |

|

18 x 63 |

18 |

± 0.9 |

63 |

+1.1/-0.4 |

24.0 |

65 |

693 |

+4/-1 |

+6/-2 |

6.7 |

|

20 x 70 |

20 |

± 1.0 |

70 |

+1.3/-0.4 |

27.0 |

72 |

770 |

+4/-1 |

+6/-2 |

8.3 |

|

23 x 80 |

23 |

± 1.2 |

80 |

+1.4/-0.5 |

31.0 |

83 |

880 |

+5/-2 |

+7/-2 |

11.0 |

|

26 x 91 |

26 |

± 1.3 |

91 |

+1.6/-0.5 |

35.0 |

94 |

1001 |

+5/-2 |

+8/-3 |

14.0 |

|

30 x 105 |

30 |

± 1.5 |

105 |

+1.9/-0.6 |

39.0 |

108 |

1155 |

+6/-2 |

+9/-3 |

18.5 |

|

33 x 115 |

33 |

± 1.7 |

115 |

+2.1/-0.7 |

43.0 |

119 |

1265 |

+7/-2 |

+10/-3 |

22.5 |

|

36 x 126 |

36 |

± 1.8 |

126 |

+2.3/-0.8 |

47.0 |

130 |

1386 |

+7/-2 |

+11/-4 |

27.0 |

|

39 x 136 |

39 |

± 2.0 |

136 |

+2.4/-0.8 |

51.0 |

140 |

1496 |

+8/-3 |

+12/-4 |

31.5 |

|

42 x 147 |

42 |

± 2.1 |

147 |

+2.6/-0.9 |

55.0 |

151 |

1617 |

+9/-3 |

+13/-4 |

36.5 |

Table 2: DIN 766 round steel link chain dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

class A |

class B |

|||||||||

|

10 x 28 |

10 |

± 0.4 |

28 |

+0.5/-0.3 |

14.0 |

36 |

308 |

+2 /-1 |

+2 /-1 |

2.3 |

|

13 x 36 |

13 |

± 0.5 |

36 |

+0.6/-0.3 |

18.0 |

47 |

396 |

+2 /-1 |

+3 /-2 |

3.9 |

|

16 x 45 |

16 |

± 0.6 |

45 |

+0.8/-0.4 |

22.5 |

58 |

496 |

+3 /-1 |

+4 /-2 |

5.9 |

|

18 x 50 |

18 |

± 0.9 |

50 |

+0.9/-0.5 |

25.0 |

65 |

550 |

+3 /-1 |

+4 /-2 |

7.5 |

|

20 x 56 |

20 |

± 1.0 |

56 |

+1.0/-0.5 |

28.0 |

72 |

616 |

+3 /-2 |

+5 /-2 |

9.2 |

|

23 x 64 |

23 |

± 1.2 |

64 |

+1.2/-0.6 |

32.0 |

83 |

704 |

+4 /-2 |

+6 /-3 |

12.0 |

|

26 x 73 |

26 |

± 1.3 |

73 |

+1.3/-0.7 |

34.0 |

94 |

803 |

+4 /-2 |

+6 /-3 |

15.5 |

|

30 x 84 |

30 |

± 1.5 |

84 |

+1.5/-0.8 |

39.0 |

108 |

924 |

+5 /-2 |

+7 /-4 |

20.5 |

|

33 x 92 |

33 |

± 1.7 |

92 |

+1.7/-0.8 |

43.0 |

119 |

1012 |

+5 /-3 |

+8 /-4 |

25.0 |

|

36 x 101 |

36 |

± 1.8 |

101 |

+1.8/-0.9 |

47.0 |

130 |

1111 |

+6 /-3 |

+9 /-4 |

29.5 |

|

39 x 109 |

39 |

± 2.0 |

109 |

+2.0/-1.0 |

50.5 |

140 |

1199 |

+6 /-3 |

+10 /-5 |

35.0 |

|

42 x 118 |

42 |

± 2.1 |

118 |

+2.1/-1.1 |

54.5 |

151 |

1298 |

+7 /-4 |

+10 /-5 |

40.5 |

Table 3: DIN 764 round steel link chain (G30 & G50) working force and mechanical properties

|

nominal size |

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|||||

|

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

|

|

10 x 35 |

12.5 |

20 |

36 |

56 |

50 |

80 |

10 |

10 |

20 |

15 |

|

13 x 45 |

20 |

32 |

56 |

90 |

80 |

125 |

13 |

13 |

||

|

16 x 56 |

32 |

50 |

90 |

140 |

125 |

200 |

16 |

16 |

||

|

18 x 63 |

40 |

63 |

110 |

180 |

160 |

250 |

18 |

18 |

||

|

20 x 70 |

50 |

80 |

140 |

220 |

200 |

320 |

20 |

20 |

||

|

23 x 80 |

63 |

100 |

180 |

280 |

250 |

400 |

23 |

23 |

||

|

26 x 91 |

80 |

125 |

220 |

360 |

320 |

500 |

26 |

26 |

||

|

30 x 105 |

110 |

180 |

320 |

500 |

450 |

710 |

30 |

30 |

||

|

33 x 115 |

125 |

200 |

360 |

560 |

500 |

800 |

33 |

33 |

||

|

36 x 126 |

160 |

250 |

450 |

710 |

630 |

1000 |

36 |

36 |

||

|

39 x 136 |

180 |

280 |

500 |

800 |

710 |

1100 |

39 |

39 |

||

|

42 x 147 |

220 |

360 |

630 |

1000 |

900 |

1400 |

42 |

42 |

||

Table 4: DIN 766 round steel link chain working force and mechanical properties

|

nominal size

|

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|

|

vertical |

horizontal |

|||||

|

10 x 28 |

10 |

12.5 |

36 |

50 |

8 |

20 |

|

13 x 36 |

16 |

20 |

56 |

80 |

10 |

|

|

16 x 45 |

25 |

32 |

90 |

125 |

13 |

|

|

18 x 50 |

32 |

40 |

110 |

160 |

14 |

|

|

20 x 56 |

40 |

50 |

140 |

200 |

16 |

|

|

23 x 64 |

50 |

63 |

180 |

250 |

18 |

|

|

26 x 73 |

63 |

80 |

220 |

320 |

21 |

|

|

30 x 84 |

90 |

110 |

320 |

450 |

24 |

|

|

33 x 92 |

110 |

130 |

380 |

530 |

26 |

|

|

36 x 101 |

125 |

160 |

450 |

630 |

29 |

|

|

39 x 109 |

150 |

190 |

530 |

750 |

31 |

|

|

42 x 118 |

180 |

220 |

630 |

900 |

34 |

|

Site Inspection

Our Service

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of High reputation Outboard Flight Bars - Conveyor and Elevator Chains – 18*50mm DIN 766 Round Steel Link Chain – Chigong, The product will supply to all over the world, such as: Liberia, Turin, Benin, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.