Europe style for Soft Eye Sling - Conveyor and elevator chains – Chigong

Europe style for Soft Eye Sling - Conveyor and elevator chains – Chigong Detail:

Category

Lifting chain, short link chain, long link chain, round link chain, chain lifting, lifting chains, Grade 50 chain, Grade 70 chain, DIN 764-1, DIN 764-2, DIN 766, Round steel link chains for chain conveyor Conveyor chain, bucket elevator chain, alloy steel chain

Application

Bucket elevator, conveyor, scraper Chains for bucket elevator, conveyor and scraper SCIC produce round steel link chains per DIN 764 (G30 & G50, 2010 version) and DIN 766 (2015 version) standards, for applications in bucket elevator, conveyor and scraper. Chains specified here shall not be used as lifting accessories, slings or any other overhead hoisting.

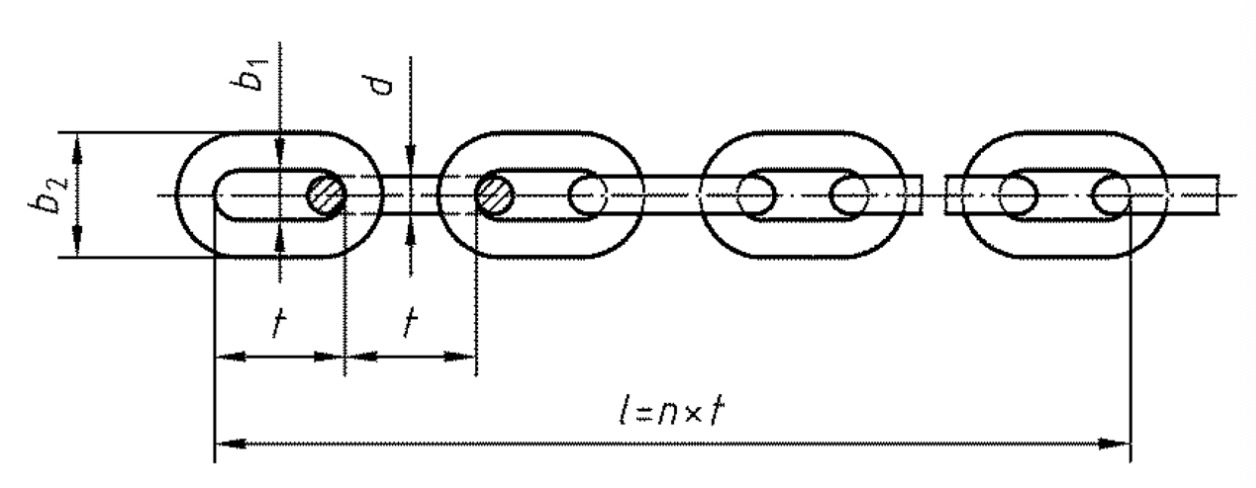

Figure 1: DIN 764 and DIN 766 round steel link chain dimensions

Table 1: DIN 764 round steel link chain (G30 & G50) dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

classA |

class B |

|||||||||

|

10 x 35 |

10 |

± 0.4 |

35 |

+0.6/-0.2 |

14.0 |

36 |

385 |

+2/-1 |

+3/-1 |

2.1 |

|

13 x 45 |

13 |

± 0.5 |

45 |

+0.8/-0.3 |

18.0 |

47 |

495 |

+3/-1 |

+4/-1 |

3.5 |

|

16 x 56 |

16 |

± 0.6 |

56 |

+1.0/-0.3 |

22.0 |

58 |

616 |

+3/-1 |

+5/-2 |

5.3 |

|

18 x 63 |

18 |

± 0.9 |

63 |

+1.1/-0.4 |

24.0 |

65 |

693 |

+4/-1 |

+6/-2 |

6.7 |

|

20 x 70 |

20 |

± 1.0 |

70 |

+1.3/-0.4 |

27.0 |

72 |

770 |

+4/-1 |

+6/-2 |

8.3 |

|

23 x 80 |

23 |

± 1.2 |

80 |

+1.4/-0.5 |

31.0 |

83 |

880 |

+5/-2 |

+7/-2 |

11.0 |

|

26 x 91 |

26 |

± 1.3 |

91 |

+1.6/-0.5 |

35.0 |

94 |

1001 |

+5/-2 |

+8/-3 |

14.0 |

|

30 x 105 |

30 |

± 1.5 |

105 |

+1.9/-0.6 |

39.0 |

108 |

1155 |

+6/-2 |

+9/-3 |

18.5 |

|

33 x 115 |

33 |

± 1.7 |

115 |

+2.1/-0.7 |

43.0 |

119 |

1265 |

+7/-2 |

+10/-3 |

22.5 |

|

36 x 126 |

36 |

± 1.8 |

126 |

+2.3/-0.8 |

47.0 |

130 |

1386 |

+7/-2 |

+11/-4 |

27.0 |

|

39 x 136 |

39 |

± 2.0 |

136 |

+2.4/-0.8 |

51.0 |

140 |

1496 |

+8/-3 |

+12/-4 |

31.5 |

|

42 x 147 |

42 |

± 2.1 |

147 |

+2.6/-0.9 |

55.0 |

151 |

1617 |

+9/-3 |

+13/-4 |

36.5 |

Table 2: DIN 766 round steel link chain dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

class A |

class B |

|||||||||

|

10 x 28 |

10 |

± 0.4 |

28 |

+0.5/-0.3 |

14.0 |

36 |

308 |

+2 /-1 |

+2 /-1 |

2.3 |

|

13 x 36 |

13 |

± 0.5 |

36 |

+0.6/-0.3 |

18.0 |

47 |

396 |

+2 /-1 |

+3 /-2 |

3.9 |

|

16 x 45 |

16 |

± 0.6 |

45 |

+0.8/-0.4 |

22.5 |

58 |

496 |

+3 /-1 |

+4 /-2 |

5.9 |

|

18 x 50 |

18 |

± 0.9 |

50 |

+0.9/-0.5 |

25.0 |

65 |

550 |

+3 /-1 |

+4 /-2 |

7.5 |

|

20 x 56 |

20 |

± 1.0 |

56 |

+1.0/-0.5 |

28.0 |

72 |

616 |

+3 /-2 |

+5 /-2 |

9.2 |

|

23 x 64 |

23 |

± 1.2 |

64 |

+1.2/-0.6 |

32.0 |

83 |

704 |

+4 /-2 |

+6 /-3 |

12.0 |

|

26 x 73 |

26 |

± 1.3 |

73 |

+1.3/-0.7 |

34.0 |

94 |

803 |

+4 /-2 |

+6 /-3 |

15.5 |

|

30 x 84 |

30 |

± 1.5 |

84 |

+1.5/-0.8 |

39.0 |

108 |

924 |

+5 /-2 |

+7 /-4 |

20.5 |

|

33 x 92 |

33 |

± 1.7 |

92 |

+1.7/-0.8 |

43.0 |

119 |

1012 |

+5 /-3 |

+8 /-4 |

25.0 |

|

36 x 101 |

36 |

± 1.8 |

101 |

+1.8/-0.9 |

47.0 |

130 |

1111 |

+6 /-3 |

+9 /-4 |

29.5 |

|

39 x 109 |

39 |

± 2.0 |

109 |

+2.0/-1.0 |

50.5 |

140 |

1199 |

+6 /-3 |

+10 /-5 |

35.0 |

|

42 x 118 |

42 |

± 2.1 |

118 |

+2.1/-1.1 |

54.5 |

151 |

1298 |

+7 /-4 |

+10 /-5 |

40.5 |

Table 3: DIN 764 round steel link chain (G30 & G50) working force and mechanical properties

|

nominal size |

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|||||

|

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

|

|

10 x 35 |

12.5 |

20 |

36 |

56 |

50 |

80 |

10 |

10 |

20 |

15 |

|

13 x 45 |

20 |

32 |

56 |

90 |

80 |

125 |

13 |

13 |

||

|

16 x 56 |

32 |

50 |

90 |

140 |

125 |

200 |

16 |

16 |

||

|

18 x 63 |

40 |

63 |

110 |

180 |

160 |

250 |

18 |

18 |

||

|

20 x 70 |

50 |

80 |

140 |

220 |

200 |

320 |

20 |

20 |

||

|

23 x 80 |

63 |

100 |

180 |

280 |

250 |

400 |

23 |

23 |

||

|

26 x 91 |

80 |

125 |

220 |

360 |

320 |

500 |

26 |

26 |

||

|

30 x 105 |

110 |

180 |

320 |

500 |

450 |

710 |

30 |

30 |

||

|

33 x 115 |

125 |

200 |

360 |

560 |

500 |

800 |

33 |

33 |

||

|

36 x 126 |

160 |

250 |

450 |

710 |

630 |

1000 |

36 |

36 |

||

|

39 x 136 |

180 |

280 |

500 |

800 |

710 |

1100 |

39 |

39 |

||

|

42 x 147 |

220 |

360 |

630 |

1000 |

900 |

1400 |

42 |

42 |

||

Table 4: DIN 766 round steel link chain working force and mechanical properties

|

nominal size

|

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|

|

vertical |

horizontal |

|||||

|

10 x 28 |

10 |

12.5 |

36 |

50 |

8 |

20 |

|

13 x 36 |

16 |

20 |

56 |

80 |

10 |

|

|

16 x 45 |

25 |

32 |

90 |

125 |

13 |

|

|

18 x 50 |

32 |

40 |

110 |

160 |

14 |

|

|

20 x 56 |

40 |

50 |

140 |

200 |

16 |

|

|

23 x 64 |

50 |

63 |

180 |

250 |

18 |

|

|

26 x 73 |

63 |

80 |

220 |

320 |

21 |

|

|

30 x 84 |

90 |

110 |

320 |

450 |

24 |

|

|

33 x 92 |

110 |

130 |

380 |

530 |

26 |

|

|

36 x 101 |

125 |

160 |

450 |

630 |

29 |

|

|

39 x 109 |

150 |

190 |

530 |

750 |

31 |

|

|

42 x 118 |

180 |

220 |

630 |

900 |

34 |

|

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Europe style for Soft Eye Sling - Conveyor and elevator chains – Chigong, The product will supply to all over the world, such as: Nigeria, Madrid, New Delhi, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.